Though there is no recorded history, it is believed that Nepal has centuries long history in brick making. Many historical structures from Licchavi era and Malla period are evident to this. Majority of brick markers in the country still produce hand-made bricks in traditional ways as they don’t have modern equipment. ACC Bricks located at Nayabazar, Morang is one of the major brick industries in the district. The industry produces more than 6 million units of bricks every season. The industry commences making of bricks with the start of the winter season every year. Ashok Bhagat, manager of ACC Bricks says that last year’s severe floods in Terai have been still hampering the industry’s production activities.

Below are some glimpses of production activities at ACC Bricks:

1. A worker shapes mud into bricks.

2. Unbaked bricks are kept in sunlight to dry.

3. Taking dry unbaked bricks to a kiln. Arranging bricks for baking (3 and 4).

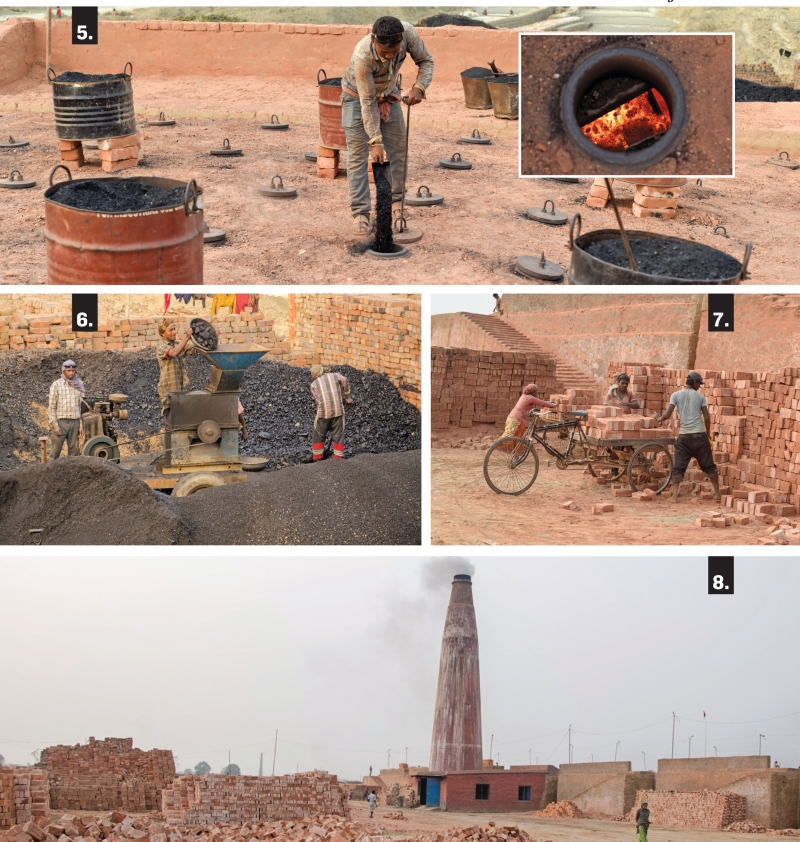

5. A worker pours coal in the brick kiln. Bricks are kept in brick kiln for more than 24 hours. Coal is added in the kiln every 10 minutes to continue the burning of fire. Burning coal inside the kiln (Inset).

6. Crushing of coals into small particles.

7. Taking baked bricks to arrange with unbaked dry bricks. This process is said to make the bricks stronger.

8. A view of chimney releasing smoke from brick kiln.